行业动态

Industry dynamic

防爆红外热成像手机用途及选购要点

2019.11.16

今天小编再给大家普及下防爆红外热成像手机的用途和选购的要点

首先我们先了解下防爆红外热像手机能做什么?

红外热成像技术在国民经济各部门发挥的作用也越来越大,应用领域不断扩大:从早期的单纯军事应用,不断发展到工农业、民用市场。如工业上的温度测量、生产过程监控、设备状态监测与故障诊断、无损检测;农业上的作物长势与产量预估、病虫害预报、农产品脱水干燥;医学上的病理诊断、疗效检测;建筑上的水渗漏、节能性能的鉴定;空调性能的检测;安防、消防行业的监控、预防性维护;以及许多基础科学研究等领域。

几乎一切装置在发生故障前都会变热,使得红外热像手机在许多应用场合成为性价比极高、非常有用的诊断工具。红外热像手机可以避免因此造成的生产停工、产量下降、能源损耗、火灾甚至灾难性故障所带来的高昂代价。 第二具体有哪些场所可以应用到:电气设备方面

第二具体有哪些场所可以应用到:电气设备方面

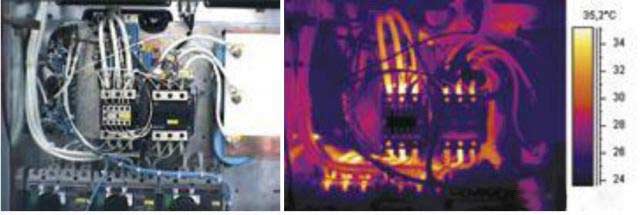

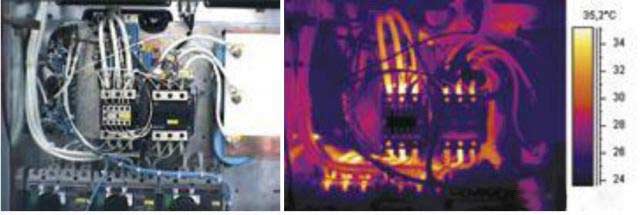

以下是电气设备中热成像技术应用的部分示例:

1.主动力源

2.开关设备

3.变压器

4.低压安装系统,即断路器板、故障电源插座/墙装插座

5.熔断器板

6.马达控制中心(MCC)

7.电气柜

机械设备类

1.泵(过热接点、保险丝故障、过载电缆等等)

2.流程阀门(打开、关闭、泄漏)

3.存储罐(淤泥界面检测)

4.输油管路(检查是否存在异常,比如定位结垢等等)

5.发动机(轴承过热、偏移、线圈过热)

6.传输带(轴承过热)

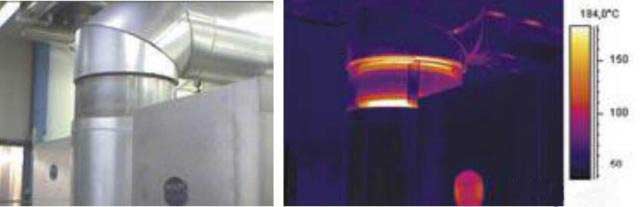

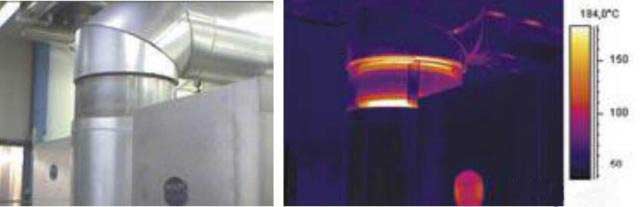

7.熔炉检测(选用针对工业高温熔炉应用领域特别设计的热像仪观测火焰。此类热像仪是监控熔炉、加热炉及锅炉等高温设备的理想工具) 知道了防爆热成像手机的用途之后,小编带大家来了解下防爆红外热像手机的选购要点,选择红外线热像最为重要的有四个指标:

知道了防爆热成像手机的用途之后,小编带大家来了解下防爆红外热像手机的选购要点,选择红外线热像最为重要的有四个指标:

第一,探测器分辨率: 一般建议选择160*120;如果分辨率选择80*60的低分辨率的成像的效果没那么好。

第二,帧频: 一般建议选择30HZ以上的,低于10HZ的尽量不要选择,无法适应大部分环境。

第三,测温范围: 建议选择两个测温范围的,比如-20℃到250℃,0-600的。

第四,测温方式:尽量选择可自动捕获 移动测温点和测温区域的机型。具有动态增强功能(MSX)的防爆红外热像仪有动态增强功能(MSX)和没有动态增强功能(MSX)的区别是,MSX功能能将这类可视细节实时叠加到红外图像中,以创建能够准确显示正在升温位置的多合一热图像。

首先我们先了解下防爆红外热像手机能做什么?

红外热成像技术在国民经济各部门发挥的作用也越来越大,应用领域不断扩大:从早期的单纯军事应用,不断发展到工农业、民用市场。如工业上的温度测量、生产过程监控、设备状态监测与故障诊断、无损检测;农业上的作物长势与产量预估、病虫害预报、农产品脱水干燥;医学上的病理诊断、疗效检测;建筑上的水渗漏、节能性能的鉴定;空调性能的检测;安防、消防行业的监控、预防性维护;以及许多基础科学研究等领域。

几乎一切装置在发生故障前都会变热,使得红外热像手机在许多应用场合成为性价比极高、非常有用的诊断工具。红外热像手机可以避免因此造成的生产停工、产量下降、能源损耗、火灾甚至灾难性故障所带来的高昂代价。

以下是电气设备中热成像技术应用的部分示例:

1.主动力源

2.开关设备

3.变压器

4.低压安装系统,即断路器板、故障电源插座/墙装插座

5.熔断器板

6.马达控制中心(MCC)

7.电气柜

机械设备类

1.泵(过热接点、保险丝故障、过载电缆等等)

2.流程阀门(打开、关闭、泄漏)

3.存储罐(淤泥界面检测)

4.输油管路(检查是否存在异常,比如定位结垢等等)

5.发动机(轴承过热、偏移、线圈过热)

6.传输带(轴承过热)

7.熔炉检测(选用针对工业高温熔炉应用领域特别设计的热像仪观测火焰。此类热像仪是监控熔炉、加热炉及锅炉等高温设备的理想工具)

第一,探测器分辨率: 一般建议选择160*120;如果分辨率选择80*60的低分辨率的成像的效果没那么好。

第二,帧频: 一般建议选择30HZ以上的,低于10HZ的尽量不要选择,无法适应大部分环境。

第三,测温范围: 建议选择两个测温范围的,比如-20℃到250℃,0-600的。

第四,测温方式:尽量选择可自动捕获 移动测温点和测温区域的机型。具有动态增强功能(MSX)的防爆红外热像仪有动态增强功能(MSX)和没有动态增强功能(MSX)的区别是,MSX功能能将这类可视细节实时叠加到红外图像中,以创建能够准确显示正在升温位置的多合一热图像。